Enhancing Product Integrity: The Role of Vision Inspection Systems in Modern Industries

In the fast-paced realm of modern industries, the pursuit of perfection and the preservation of product integrity have become more critical than ever before. As consumer expectations rise and global competition intensifies, manufacturers are turning to advanced technologies to uphold uncompromising quality standards. Among the transformative tools driving this evolution is the Vision Inspection System – an innovation that is revolutionizing how industries safeguard and enhance product integrity.

Unveiling the Vision Inspection System

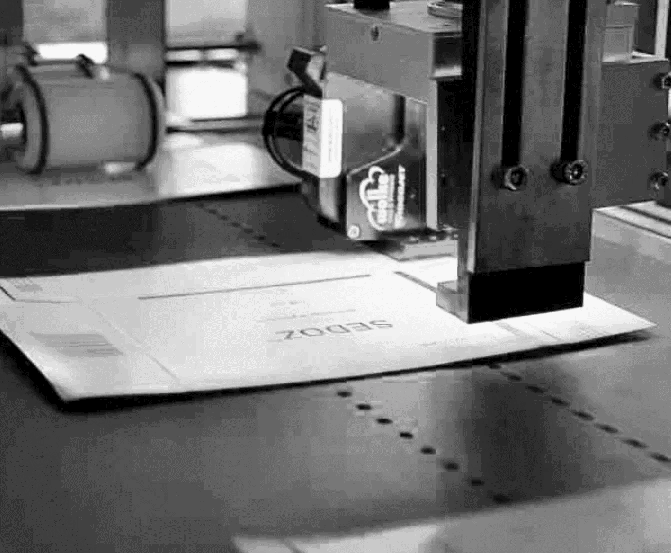

Imagine a system equipped with the prowess to meticulously analyze products down to the finest detail, surpassing human capabilities with unmatched accuracy. The Vision Inspection System is precisely that – a sophisticated solution powered by cutting-edge imaging, artificial intelligence, and machine learning algorithms. This technological marvel is designed to inspect and assess products in real-time, ensuring that each item meets the highest standards of quality.At its essence, the Vision Inspection System represents a paradigm shift in quality control, offering a unique vantage point to detect defects, irregularities, and deviations that might elude human perception. From assembly lines to packaging operations, this technology is reshaping the landscape of product integrity.

The Symphony of Precision and Assurance

The Vision Inspection System brings a host of advantages that transcend conventional quality control methods:

1. Exquisite Precision:

The system's ability to capture and analyze intricate product details ensures that even the most subtle imperfections are unveiled, safeguarding the overall integrity of the product.

2. Immediate Vigilance:

In contrast to manual inspections, the Vision Inspection System operates in real-time, enabling the instantaneous identification of defects. This swift response minimizes the chances of substandard products entering the market.

3. Consistency and Reliability:

Human inspectors may encounter variances in judgment due to factors like fatigue. The Vision Inspection System, on the other hand, adheres consistently to programmed standards, ensuring uniformity across production batches.

4. Elevated Efficiency:

With its rapid processing capabilities, the system can inspect products at high speeds, resulting in heightened production efficiency and increased throughput.

5. Data-Driven Insights:

By aggregating and analyzing extensive datasets, the Vision Inspection System empowers manufacturers with invaluable insights that can be leveraged to optimize processes, preclude future defects, and refine product design.

Transforming Diverse Industries

The versatility of the Vision Inspection System makes it an invaluable asset across a spectrum of industries:

1. Manufacturing Excellence:

From intricate components to complex assemblies, manufacturers can ensure that each element adheres to rigorous quality standards before integration into the final product.

2. Pharmaceutical Precision:

In the pharmaceutical sector, the system verifies pill counts, monitors packaging integrity, and identifies any irregularities in labeling, contributing to patient safety.

3. Edible Assurance:

For consumables, the Vision Inspection System examines packaging seals, detects contaminants, and guarantees uniformity in appearance and size.

4. Package Perfection:

In the realm of packaging, the system confirms label placement, verifies barcode readability, and evaluates the overall integrity of the package.

5. Electronics Evolution:

From circuit boards to intricate components, the system can identify soldering defects, pin misalignments, and other imperfections in electronic products.

Paving the Path to a Flawless Future

In an era defined by technological prowess, the Vision Inspection System offers a glimpse into the future of product integrity and quality assurance. Its remarkable ability to amplify accuracy, speed, and data-driven decision-making is propelling industries towards a new horizon of excellence.In a world where product integrity is non-negotiable, the Vision Inspection System stands as a testament to the potential of technology to reshape manufacturing processes, fortify product quality, and establish entirely new standards of assurance. As industries wholeheartedly embrace this transformative tool, they are charting a course towards a future where product integrity becomes synonymous with success, carving a niche for themselves in a competitive global landscape that values nothing short of perfection.